Decoding plant reliability in manufacturing and a process to reach there.

Process manufacturers typically operate in data-rich environments and know their plants inside out. While they know their assets and how their resources are deployed, they are often unaware of factors contributing to optimal asset performance. Even if this information exists within the manufacturing ecosystem, the plant maintenance and operational heads don’t really know how to use it to achieve optimum plant productivity.

Studies reveal that frequent downtimes at process manufacturing plants can result in nearly $15000 per hour of lost revenue. Digitalization of the maintenance process and proactive asset performance management directly contribute to saving this cost. Prioritizing plant reliability becomes the only way to improve overall operations and mitigate unplanned downtimes.

But what is plant reliability, and what processes need to be institutionalized to achieve it? In this article, we will discuss what reliability means for manufacturing and lay out a six-step process to devise a plant reliability strategy for a manufacturing plant effectively.

What is plant reliability, and how can you measure it?

Any reliable system accounts for its safety and trustworthiness while ensuring minimal maintenance costs. For plant assets, reliability can depend on performance, condition, maintenance needs, and availability. An asset reliability check can be done based on factors like frequency of maintenance or repair costs, number of malfunctions, unexpected downtimes, and more.

Six steps to creating an effective reliability plan at your plant.

The right team can make or break reliability goals- from top to bottom.

Effective leadership, skilled personnel, and onsite-plant operations team must be aligned with accomplishing plant reliability goals.

Achieving reliability is a team effort and a continuous improvement process. Designated team champions have to be distributed within Operations, Maintenance, and Engineering along with sufficient alignment around their common goals & individual targets. This way, every individual is well aware of their role in constantly improving the plant and understands their dependencies on the other teams. There has to be also a Reliability Leader who helps drive this initiative

For a successful plan, having the right mindset for asset reliability is as important as relevant skills, processes & technical understanding.

Since achieving reliability requires continuous effort, you can try to define your target numerically & align every department’s target accordingly. This target & its deadline needs to be agreed upon by each department-operations, maintenance, engineering, and the subsequent KPIs that befall them individually.

It is critical that all teams uphold this goal as their guiding principle and implement it through individual responsibilities every day.

3. Adapting Predictive Maintenance (PdM) approach

Plant reliability is also heavily dependent on asset health & reliability. The approach towards asset reliability is centered around the plant maintenance methodology chosen.

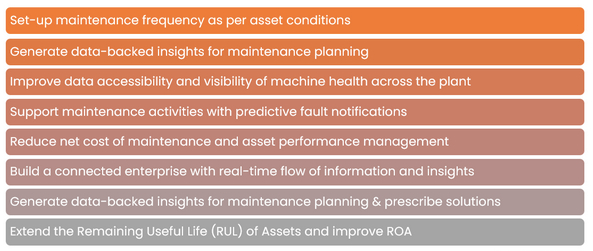

An advanced framework like predictive maintenance alongside numerous assets and operations can speed up the process of obtaining plant reliability. By proactively anticipating flaws or anomalies within the plant and addressing them, reliability objectives can be progressively achieved.

And when you proactively work towards fixing them, you can see your maintenance costs and the dreaded plant downtimes plummet instantly. Also, by understanding what caused these failures, your teams can work towards optimizing their maintenance strategy in the future.

4. Having a best practices checklist for assured equipment reliability

It is not enough to be proactive at one time; it has to become a process for excellence in reliability. For this, rigorous observation of what worked needs to be executed..

Best practices for different plant segments and units can be documented for standardized records and accessibility. Mainly for equipment reliability which requires defined steps, having a list of executables becomes highly essential. These practices are initially set for a particular type of machine in a plant -like a gearbox which can be applied for gearboxes across multiple plants for the same organization to benefit from learnings.

This can help your team focus on improving reliability at the plant, bit by bit, and avoid recurring mistakes alongside employing PdM.

5. Prioritizing critical assets first

Your plant might have critical equipment that causes the most impact – both financially and operationally when down, like a kiln in a cement plant.

So to reduce this unpredictable impact, you can prioritize these assets and implement a model like Predictive Maintenance to fix issues on priority beforehand. Predictive Maintenance can also improve equipment reliability as it works toward assuring asset performance and health around-the-clock through continuous evaluation.

6. Assessing your Reliability plan’s progress

Using your goals & best practices checklist, perform regular audits to check for any shortcomings. Organize audits as frequently as monthly or quarterly, based on your process durations. Check if your charted reliability program progress is aligned with your monthly/quarterly goals.

Continuous improvement requires continuous learning too. Make a detailed implementation plan with clear-cut steps for each task for every department involved and skill improvement and tool usage training at periodic intervals. Skills like vibration monitoring.

This practice keeps your plant and teams’ performance in constant check. Also, assessing highlights hidden improvement areas that may be hindering your plant’s reliability.

Conclusion:

A well-articulated plant reliability plan and set targets can be the driving force towards rapidly fulfilling your reliability goals. Since consistency is key to realizing this goal, it requires a combined proactive effort from leadership, stakeholders, and staff.

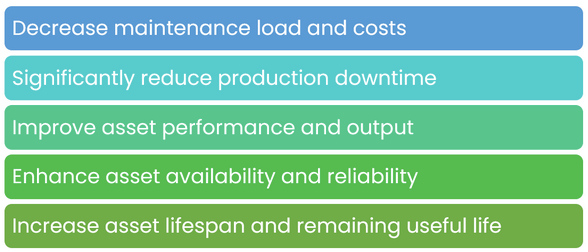

At Infinite Uptime, we provide cutting-edge solutions to implement predictive maintenance programs, seamlessly improving your plant’s reliability. With plant reliability, we help manufacturers across the globe see faster results by significantly improving plant efficiency, fewer downtimes, and better quality using predictive maintenance.

Want to achieve faster plant reliability? Get in touch with us today to schedule a free demo!